I recently acquired a Makerbot Thing-O-Matic, a printer I selected due to its apparent ubiquity and to its price — under $1000 if you do the assembly yourself. With the heady optimism and overconfidence borne of having not yet attempted something, I dove in with my boxes of parts and wiki instructions. Besides, I build stuff all the time, which is the point of having a 3D printer in the first place.

Another appeal of a largely community-supported machine is the lack of need to talk to tech support, which is usually a dismal experience. I contacted a tech support for a popular anti-virus program which would occasionally inexplicably shut down when I was using it on public networks. Tech support’s answer: don’t use public networks.

At any rate, aside from backtracking a few times (the combination of extra parts and following some outdated instructions led to a few false starts, and a quirk or two of design, assembling the little beast wasn’t a problem. I didn’t start causing my own problems until I actually started printing.

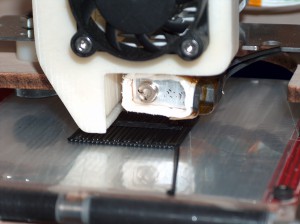

I calibrated and made little adjustments in order to improve my print quality:

- The stepper extruder didn’t have enough clearance to grip the filament, so I removed a washer

- The extruder had trouble pushing the plastic through, so I increased the temperature

- The raft was blobby, so I lowered the nozzle relative to the build platform

- The raft didn’t stick to the build platform, so I raised the temperature of the build platform

After all this tweaking and adjusting, I was able to print some pretty good looking calibration cubes, that more or less looked like the pictures I was seeing on the web. However, absolutely all of these adjustments were exactly the wrong thing to do. I had managed to put together a set of tweaks that made fairly good, accurate prints, that warped crazily as soon as they were finished.

- The stepper extruder doesn’t have much clearance for the filament because it grips the filament very tightly. The filament should have bite marks from the extruder. Putting the washer back in, I cut the filament in a “v” shape before feeding it in so that it could be gripped.

- Turns out I could actually lower the temperature of the extruder, now not having any trouble pushing filament through the nozzle.

- Having the nozzle so close to the build platform was pressing the raft right into whatever I was printing. Raising the nozzle opened up the raft and allowed it to actually come off.

- With the nozzle farther away from the build platform, it no longer tended to drag the plastic away from the platform, and the platform temperature could be lowered as well.

Weirdly, even with things boldly out of whack, I was able to produce some very good prints, although they took a lot of clean-up and sanding, and warping was a real issue. The look of things hasn’t changed much, but less clean-up is necessary and less warping means more things will actually come out shaped closer to how they were designed.